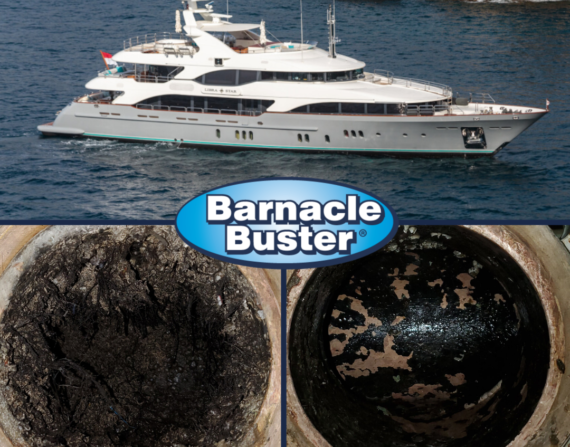

OUR TEAM HAS OVER 45 YEARS OF EXPERIENCE

DESCALING MARINE WATER SYSTEMS

Our sea water system flushes are performed using the benchmark product in marine growth removal, Barnacle Buster.

- Engine Overheating?

- A/C Not Cooling?

- Clogged Pipes?

When Should I flush My Engine?

Heads Leaving Nasty Odors, Not Flushing, Backing Up?

Using Trac's Sew Clean and a vacuum based flushing system instead of a pressurized flushing system commonly used, we can safely flush an entire black water system with up to 30 heads.

For this application each head needs to be removed so that they can be connected via hoses to a central manifold system. Each manifold is then linked to other manifolds via larger hoses and brought back to our vacuum flushing system’s tank, we then close the flushing loop by making a connection at the vacuum pumps. This process allows us to flush the entire system, including all the risers and main trunk lines.

Depending on the vessel size and amounts of heads, this application is performed over a 4 to 5 days’ time period

What our customers have to say!

Island Time

“ Barnacle Buster cleans the corrosion out of vital marine engine cooling systems and marine ac units. You will be amazed how much a coolant soak or ac lines flush will come out after

Nino

“ Just cleaned eight salt water heat exchangers off yanmar diesels. This product is the real deal! Tried other products which didn’t work on breaking down scaling and salt deposits. After soaking in Barnacle

Haywood M Cross Jr

“ It does work! It helps to remove barnacle and corrosion build up. But if you have thick rust layer in cooling system I suggest to use evaparust coolant rust remover and let it